Receiving in Mobile

1.6 min read

|All receiving transactions will be completed on the mobile device (mobile.scoutsft.com)

To receive in mobile,

- Login to https://mobile.scoutsft.com/.

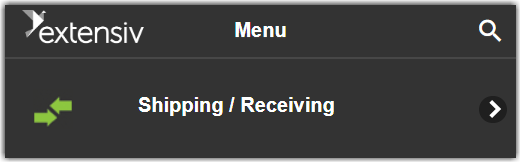

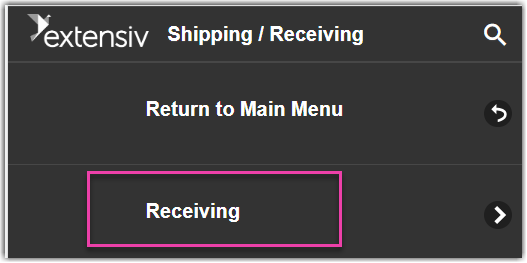

- Navigate to Shipping/Receiving > Receiving.

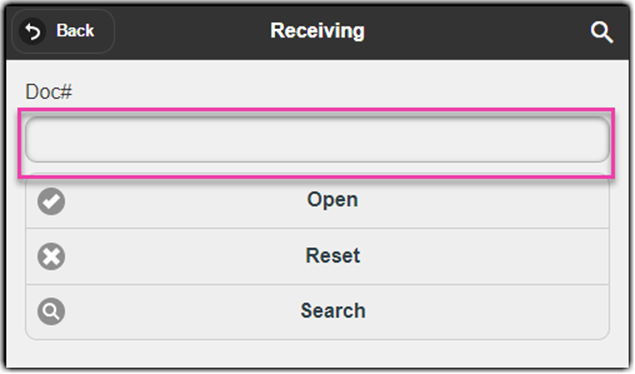

- Scan the Receiving Order barcode into the Receiving Order Number field.

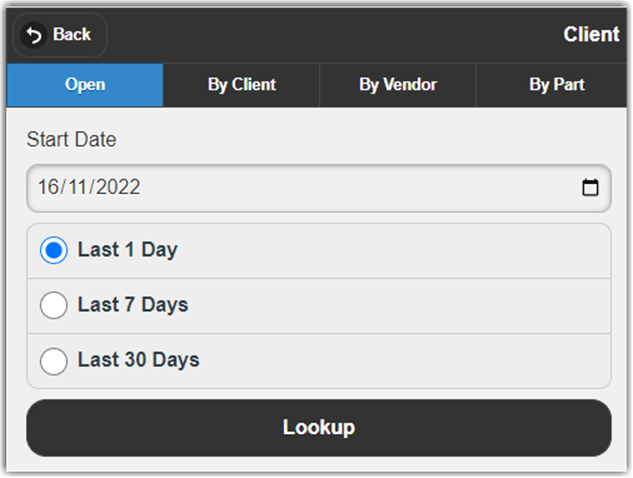

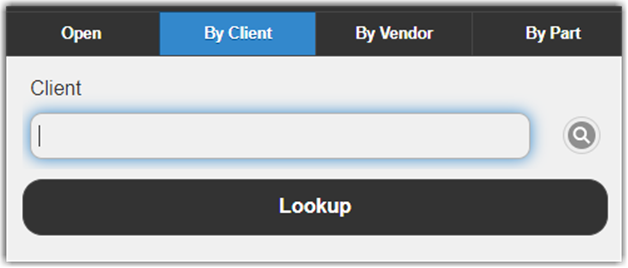

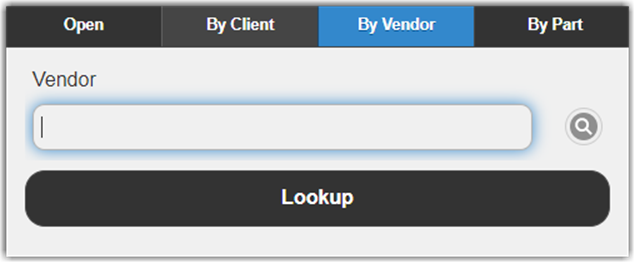

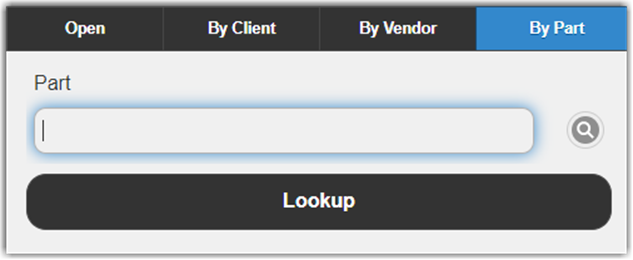

- You can also use the Search functionality to look up the receiving order. Search functionality allows you to search by Open status, Client, Vendor, or Part.

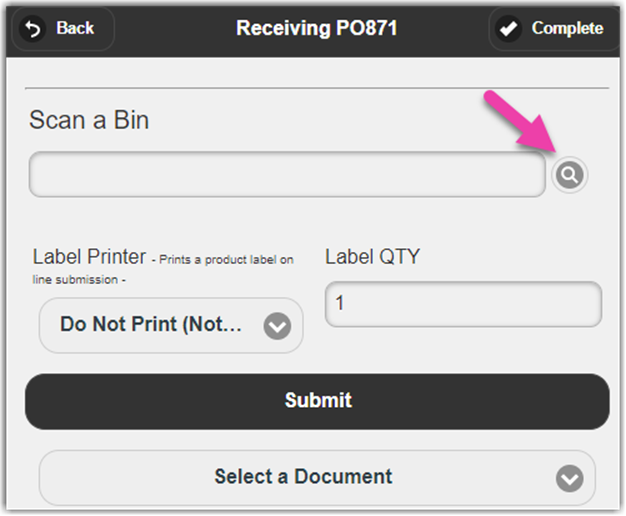

- Scan the bin where the inventory will be physically placed (whether temporarily or for long-term storage). You can also use the Search icon to look for an existing bin.

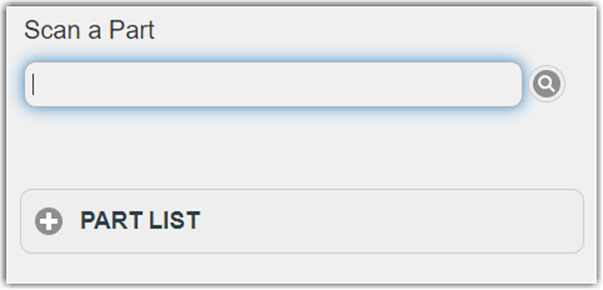

- Next, Scan a Part to be received, or click Part List to expand and select from the Part List.

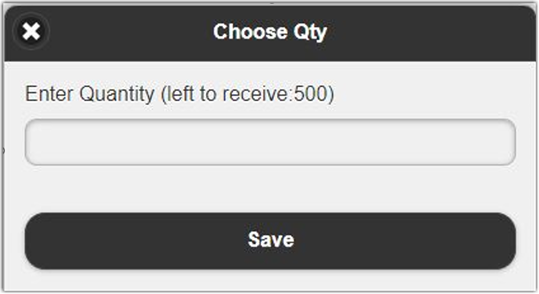

- Enter QTY (Quantity) to receive.

- Continue with each part in the order.

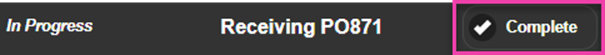

- Click the Complete in the top right-hand corner. Order will automatically close and return to the Receiving menu.

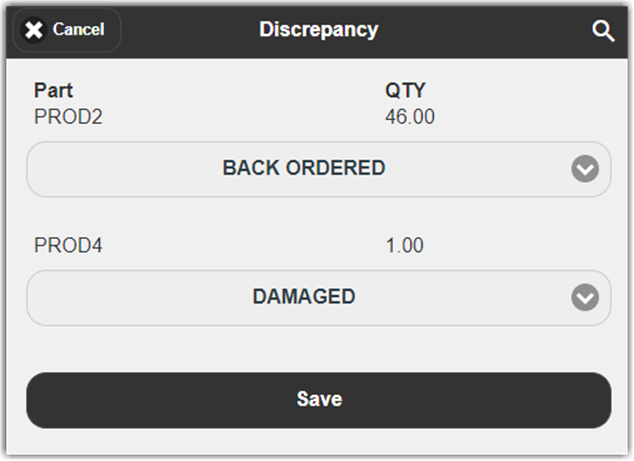

Discrepancies

To account for discrepancies,

- If the receiving process is complete, but all items have not been received on the PO, click Complete.

- When the discrepancy window opens, select the appropriate kind of discrepancy. The options include Back Ordered, Damaged, or Wrong Item(s). These are used to notate why there is a discrepancy between what was ordered and what was received. A reason code is not required.

The discrepancy codes can be customized in Settings > Reason Codes. For more information, please see our help article for Reason Codes.

- Click Save to close and complete the receiving process.

Adding Parts on the Fly

To add parts,

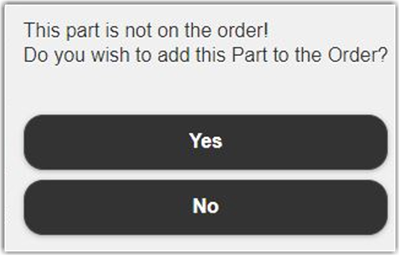

- If a part was not on the Receiving Order, you can scan the part and the mobile device will ask if you want to add the part, then click Yes to confirm.

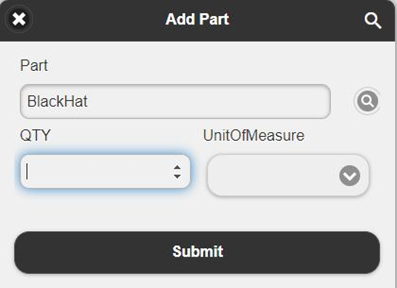

- You will be asked to enter the expected QTY (Quantity) on the Receiving Order.

- Once added, you can continue with the standard receiving process. When the Receiving process is complete, you will be promoted to accept the discrepancy as shown above, and choose a reason code, if desired, but not required.

Receiving Assets

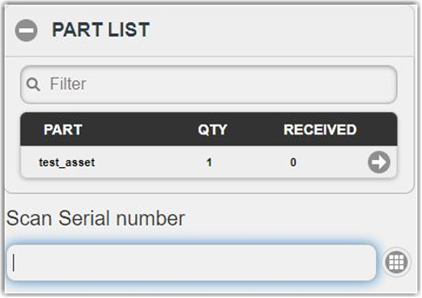

To receive assets through scanning the part being received,

- Enter or Scan the Serial Number.

- Repeat for each part on the receiving order.

- Click Complete when done.

- You can only receive one asset at a time.

- Serial numbers can be uploaded in bulk via SNAP but must be a continuous run of serial numbers. Example: SERIAL_1, SERIAL_2, SERIAL_3, and so on.

- If the Remove Prefix/Suffix was used in the Part Record, the scan will take away the prefix/suffix.

Receiving Lots

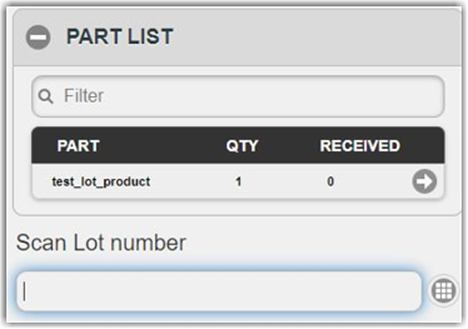

To receive lots through scanning the part being received,

- Enter or Scan Lot Number

- Enter the QTY (quantity).

- Repeat for each part on the receiving order.

- Click Complete when done.

You can receive 1 lot code at a time. Lot Numbers can be uploaded in bulk via SNAP.