Understanding Directed Putaway Logic

3.4 min read

|This article reviews the logic 3PL Warehouse Manager follows when assigning locations to items when using the Directed Putaway feature. There are two distinct progressions that directed putaway uses to search for a location to store a given receipt line item:

- Identify potential location groups suitable for storing this item

- Evaluate item requirements to identify a putaway location within the desired group

Progression 1: Identify a location group

3PL Warehouse Manager uses the following progression to identify the location group to use when searching for a putaway location.

- Item Configured for Directed Putaway: To qualify for directed putaway, an item must have one or more of the following defined: Packaging Zones, Movable Unit Zones, Overallocated Zones, or Preferred Location. If one or more of these is configured, the process moves to Step 2. Otherwise, directed putaway fails for this item.

- Search Overallocated Zones: If an overallocated zone is defined, and overallocated orders exist, directed putaway searches locations in each overallocated zone to find one capable of holding the item (covered in progression 2 below). If the search succeeds, directed putaway assigns the matched location; if no match is found, the process continues to Step 3 to attempt to locate a match.

- Preferred Location: If there is room in the preferred location, or if you have selected “Always use this location”, directed putaway uses the preferred location. Otherwise, the process continues to Step 4.

- Movable Unit Zones: If a movable unit zone is defined, and the line item is on a movable unit, directed putaway searches locations in each movable unit zone to find one capable of holding the item (covered in progression 2 below). If the search succeeds, directed putaway assigns the location; if not, the process continues to Step 5.

- Packaging Unit Zones: If a packaging unit zone is defined, and the line item is NOT on a movable unit, directed putaway searches locations in each packaging unit zone to find one capable of holding the item (covered in progression 2 below). If the search succeeds, directed putaway assigns the location; if not, directed putaway fails.

Progression 2: Evaluate item requirements

After identifying a location group to search for a putaway location, 3PL Warehouse Manager uses the following progression to evaluate individual locations against the requirements of the specific line item.

Directed putaway uses the first location it finds that meets the item’s specified criteria—there is no location hierarchy or preference within a given group.

-

Evaluate item restrictions: Determines if a location meets all restrictions specified in the item’s directed putaway configuration

- Rejects location if one of its zones does not match both the item’s zone type and zone name exactly

- Rejects location if it is configured “Store Movable Units Only” and the line item is not on a movable unit

- Rejects location if it contains items that are different from the receipt item and the receipt item is not configured to “Store with Other Items”

- Rejects location if it contains lots that are different than the receipt items and the receipt item is not configured to “Store Multiple Lots”

- Rejects location if it contains items with an expiration date that is different and falls outside the receipt item’s “Mixed Expiration Days Threshold”

-

Evaluate location capacity: Determines if there is sufficient room in the location for the line item

- If receipt item is on a movable unit:

- Rejects location if receipt item is on an MU and MU height is greater than the location height

- Rejects location if receipt item is on an MU and the number of currently stored MUs is greater than, or equal to, the value specified in “Max # of Movable Units”

- Rejects location if the volume of currently stored items, plus the receipt item, is greater than the location volume

- Rejects location if its maximum weight is less than the movable unit’s declared weight

- If receipt is not on a movable unit:

- Directed putaway fails if the item has no packaging unit dimensions to calculate volume and weight

- Rejects location if the calculated volume of the receipt item is greater than the remaining volume in the location

- Rejects location if its maximum weight is less than the receipt item’s calculated weight

- Rejects location if its maximum weight is less than the sum of the weight of its current contents plus the calculated weight of the receipt item

- If receipt item is on a movable unit:

- Assign recommended putaway location: If the location hasn’t been rejected, use it as the directed putaway location. If all locations are rejected, directed putaway does not assign any location to the receipt line item. Workers must assign the location manually, and administrators should re-evaluate directed putaway configuration to determine why it failed to identify a valid putaway location.

Configuration run-through

Reference the image below for the following flows.

Item is received, and orders are waiting:

- The item will be placed in Forward Picking zone, granted space is available.

- If no space is available in Forward Picking, the item will be placed in A-1-A (Preferred Location).

- If no space is available in either Forward Picking or A-1-A, the item will be placed in Primary zone, granted space is available based on the search criteria.

- If no space is available in the previous steps, the item will not be assigned a location and will have to be manually assigned.

Item is received:

- The item will be placed in A-1-A, granted space is available.

- If no space is available in A-1-A, the item will be placed in the Primary zone if all conditions are met.

- If no space is available in the previous steps, the item will not be assigned a location and will have to be manually assigned.

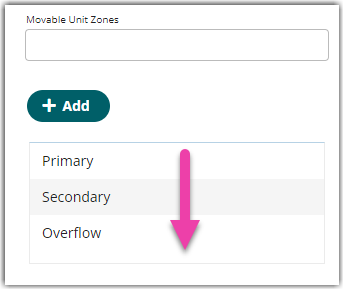

If you had multiple Movable Unit Zones, Packaging Unit Zones, or Overallocated Zones, 3PL Warehouse Manager evaluates the zones in the order they are listed from top to bottom.

Search is completed Primary, Secondary, then Overflow.