Defining Units of Measure

When creating or editing an item, you use the Units of Measure section to define the specific primary and packaging unit details. This article reviews how to define units of measure (UOM) for an item.

The four most common units of measurement (UoM) are eaches, inner cartons, cartons, and pallets. Knowing the UoM that best fits the organization of your inventory is crucial because it informs the way you want to ship and receive inventory. For a full list of supported UoMs, see Understanding Units of Measure.

Units of Measure

The Units of Measure sub-section is used to select the relevant measurement standard for an item. We highly recommend selecting the same measurement standard as defined in your warehouse setup.

When defining integral units (e.g., eaches, cartons, pallets), please keep in mind that decimals are not supported for primary, secondary, and packaging units. Decimals are also not supported when specifying a quantity to receive and ship integral units. (This does not apply to units that often require decimals, such as gallons, feet, and pounds.)

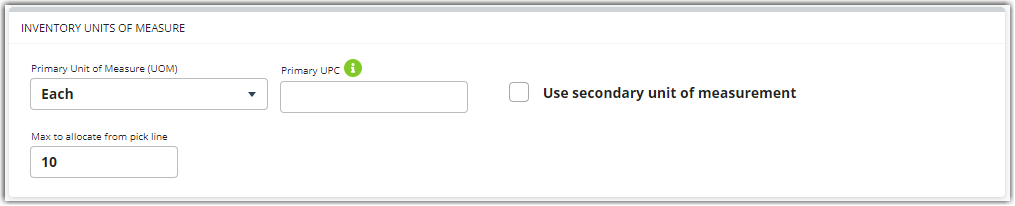

Inventory Units of Measure

The Inventory Units of Measure sub-section defines the inventory unit type for an item. While items are primarily tracked by a primary unit, 3PL Warehouse Manager also allows you to specify a secondary UoM to receive and ship by. Secondary UoM is most often used if you plan on splitting primary UoM.

-

Primary Unit of Measure (UOM): The smallest unit tracked for an item when received, stored, and shipped

- Primary UPC: Barcode value associated with the primary unit—used to identify the item

-

Use secondary unit of measure: When selected, allows you to track an additional UOM

- Secondary Unit of Measure (UOM): Unit type tracked as the secondary UOM

- Primary Units Per Secondary UOM: The quantity of primary units in a secondary unit

- Secondary UPC: Barcode value associated with the secondary unit—used to identify the item

- Max to allocate from pickline: When Replenishments is enabled, an order is allocated from pickline locations when its quantity is equal to or less than this value, and from bulk storage when it exceeds this value. This limits the need to pick an order from both pickline and bulk storage. This prevents large orders from being allocated from the pickline letting them instead be allocated from bulk storage. See our article Replenishments to learn more about this feature.

Packaging Unit

The Packaging Unit fields determine the packaging type and dimensions for an item.

- Packaging Unit of Measure (UOM): The unit which the primary units are packaged into

- Primary Units Per Package: The total quantity of primary units packed into a packaging unit

- Packaging UPC: Barcode value associated with the packaging unit—used to identify the item

- Length/Width/Height/Total Area/Total Volume/(Gross) Weight: The relevant dimensions of the packaging unit

- Net Weight: The total weight of the primary units without the weight of the packaging unit

- This item is pre-packaged: For pre-packaged items. This setting lets Small Parcel and SmartScan simplify the packing process by auto-packing these items so you don't have to do anything special at the pack station. Note: You can only activate this setting for items with a non-zero ‘Length’, ‘Width’, and ‘Height’. You can modify the values but you can't clear them or set them to zero while this setting is active.

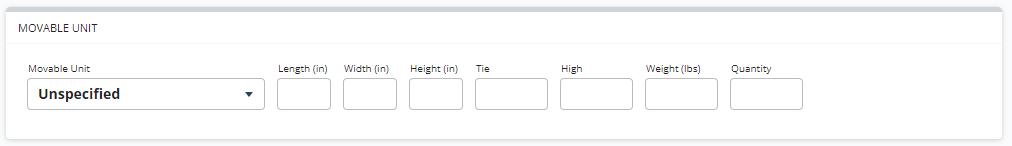

Movable Unit

The Movable Unit sub-section is used to specify movable unit (MU) details for an item if you plan on tracking by MU. For more information, please see Understanding Movable Units.

- Movable Unit: The MU type associated with this item, configured under Admin > Movable Units

- Length/Width/Height/Weight: The dimensions of the selected MU type (auto-populates based on MU configuration and allows editing as needed)

- Tie: The total number of primary units stored horizontally on the MU

- High: The total number of primary units stored vertically on the MU

- Quantity: The total number of primary units that fit on 1 MU (helps the system properly split MUs when you choose to 'Split Movable Unit' upon receiving the item)

Once you've defined units of measurement for an item, you can continue to the next configuration section—Creating Item Assemblies. If you'd like to come back and edit the item at a later time, don't forget to click Save.