Understanding Count vs Count Less Other UOMs

2.7 min read

|This article is about the Billing Manager app, not the Billing Wizard in 3PL Warehouse Manager. To learn about the Billing Wizard, please refer to the articles in the Billing Setup.

Overview

This article explains the difference between 'Count' and 'Count Less Other UOMs' (Units of Measure) when the selected counting unit is based on the item level. Sample scenarios are provided to illustrate how the rate is applied.

When creating rates in Billing Manager and you intend to charge based on the item-level setup of Units of Measure—such as primary unit, secondary unit, packaging unit, and pallet—you'll likely want to calculate the charge using either 'Count' or 'Count Less Other Units of Measure

Count

This applies a straightforward logic when applying a rate.

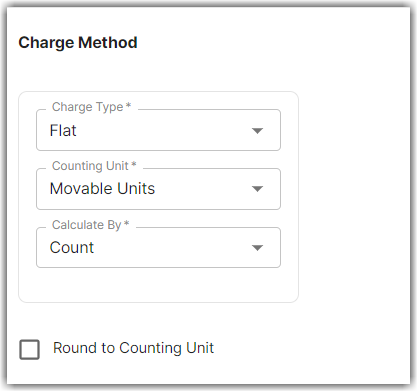

Sample Scenario: You selected Movable Unit as your counting unit and calculate by Count. Let's say the charge amount for this rate is $20.00. Also, the Round to Counting Unit is not enabled.

Question: How will the system charge in the following scenario?

Given that the transaction involves a total of 123 primary units, with the following unit breakdown:

- Secondary Unit: 10 primary units per unit

- Packaging Unit: 10 primary units per unit

- Movable Unit: 100 primary units per unit

Answer: Since there are 123 primary units, the system will count this as 1.23 movable unit since 1 movable unit is consists of 100 primary units (123 / 100 = 1.23). The system will apply a charge of $24.60 for this transaction.

Computation: 1.23 movable unit * $20 = $24.60

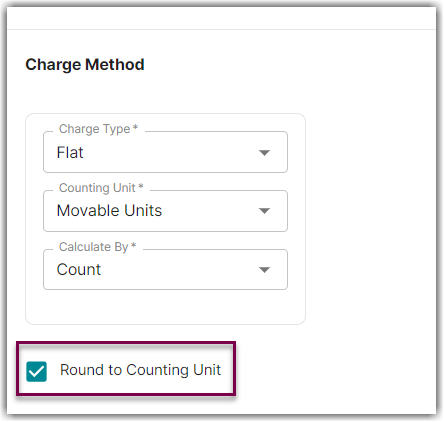

Round to Counting Unit is enabled

If Round to Counting Unit is enabled, the system will apply a full fee. So if there is a fractional quantity that makes up a pallet in a receipt, the system will charge a fee for a full pallet.

As shown in below image, the Round to Counting Unit is checked. You selected Movable Unit as your counting unit and calculate by Count. Let's say the charge amount for this rate is $20.00.

Question: How will the system charge in the following scenario?

Given that the transaction involves a total of 123 primary units, with the following unit breakdown:

- Secondary Unit: 10 primary units per unit

- Packaging Unit: 10 primary units per unit

- Movable Unit: 100 primary units per unit

Answer: Since we have 123 primary units, this results in 1.23 movable units. With Round to Counting Unit enabled, the system treats this as 2 movable units. A full pallet fee is charged for the remaining 23 primary units.

Computation: 2 movable units * $20 = $40.00 for 1.23 movable units.

Count Less Other UOMs

The idea is based on how many primary units there are for secondary unit, packaging units and movable unit.

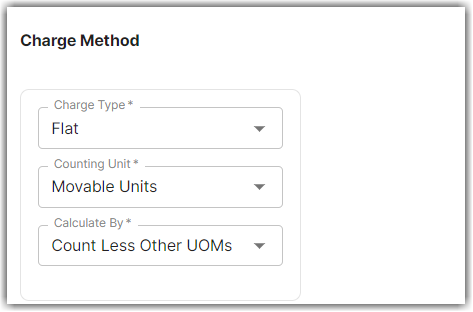

Sample Scenario: You selected Movable Unit as your counting unit and calculate by Count Less Other UOMs. Let's say the charge amount for this rate is $20.00.

Question 1: How will the system charge in the following scenario?

Given that the transaction involves a total of 123 primary units, with the following unit breakdown:

- Secondary Unit: 10 primary units per unit

- Packaging Unit: 10 primary units per unit

- Movable Unit: 50 primary units per unit

Answer: With Count Less Other UOMs, the system will only account for a full pallet, which consists of 50 primary units. This leads to 2 movable units being charged, leaving 23 primary units unaccounted for.

Computation: 2 movable units * $20 = $40.00 for 2 movable units (100 primary units total).

Question 2: What can be done so the remaining 23 primary units are also charged?

Answer: Create another rate for packaging units and another rate for primary units. Make sure that you will be using the Count Less other UOMs when calculating the rate on all unit levels.

If you have 3 rates with Count Less Other UOMs for movable unit, packaging unit, and primary unit, the system will charge for 2 movable units (100 primary units), 2 packaging units (20 primary units) and 3 primary units.

Question 3: Let's say you also created a rate for secondary unit calculated by count less other UOMs. In above example, we have the same quantity of primary units for secondary and packaging unit. Which rate will the system run to charge the 20 primary units?

Answer: A priority is in place so the system knows which of these rates to run.

- Primary Unit

- Secondary Unit

- Packaging Unit

- Movable Unit

Therefore, the system will execute the rate for the secondary unit and will not execute the rate for the packaging unit, based on the priority order. The transaction with 123 primary units will be counted as 3 primary units, 2 secondary units (equivalent to 20 primary units), and 2 movable units (equivalent to 100 primary units).